While applying ac voltage true ac electromagnets generate alternate magnetic field.

Why use laminated cores in electromagnets.

A magnetic core is a piece of magnetic material with a high magnetic permeability used to confine and guide magnetic fields in electrical electromechanical and magnetic devices such as electromagnets transformers electric motors generators inductors magnetic recording heads and magnetic assemblies it is made of ferromagnetic metal such as iron or ferrimagnetic compounds such as ferrites.

Laminated magnetic cores are made of stacks of thin iron sheets coated with an insulated layer which lie parallel to the lines of flux.

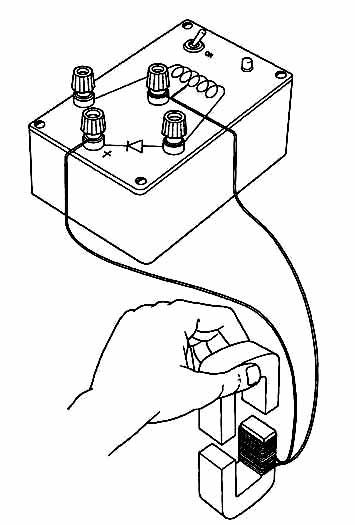

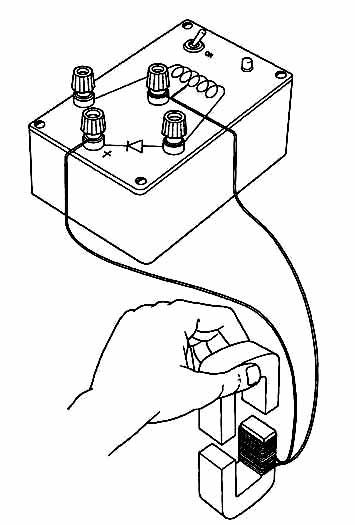

One is dc electromagnets with built in ac to dc converters rectifiers.

The core is laminated to reduce these to a minimum as they interfere with the efficient transfer of energy from the primary coil to the secondary one.

Another is true ac electromagnets made of laminated electrical steel core lamination.

A laminated core 10 including a plurality of segment core sheets 13 spirally wound and laminated in layers while connecting portions 12 connecting the adjacent segment core sheets 13 are bent ends of the segment core sheets 13 are aligned with each other and the connecting portions 12 in the adjacent layers are circumferentially displaced relative to each other the connecting portions 12.

These insulation layers serve as barriers to prevent eddy current so that it can flow only through the narrow loops within each single lamination layer.

The core is not designed to have any currents flow through it.

Why does the strength of electromagnet increase when its soft iron core is laminated.

Laminated core is a rectangular shaped type of soft magnetic core.

It is however a conducting loop that experiences a changing magnetic field it will therefore have small currents induced in it these are called eddy currents.

Which has been specially designed to carry large input and output power transmissions since loss due to eddy currents is less.